From classic spaghetti to irresistible gnocchi, pasta is a cornerstone of our daily diet and culture. But have you ever wondered what lies behind the production of these beloved products? Pasta plants are the beating heart of this process, ensuring that every pasta dish achieves perfection and meets the expectations of consumers and food companies alike. In this comprehensive guide, we will explore the secrets and technologies behind the production of both dried and fresh pasta, revealing how raw materials transform into the cherished final product.

Dry pasta plants are designed to produce pasta intended for long-term storage. The process begins with extrusion or lamination of the dough, followed by cutting into desired shapes. A key element of these plants is controlled drying, which removes moisture from the pasta, allowing it to be stored for extended periods without deteriorating. This type of pasta is ideal for large-scale distribution and export due to its long shelf life and resilience during transportation.

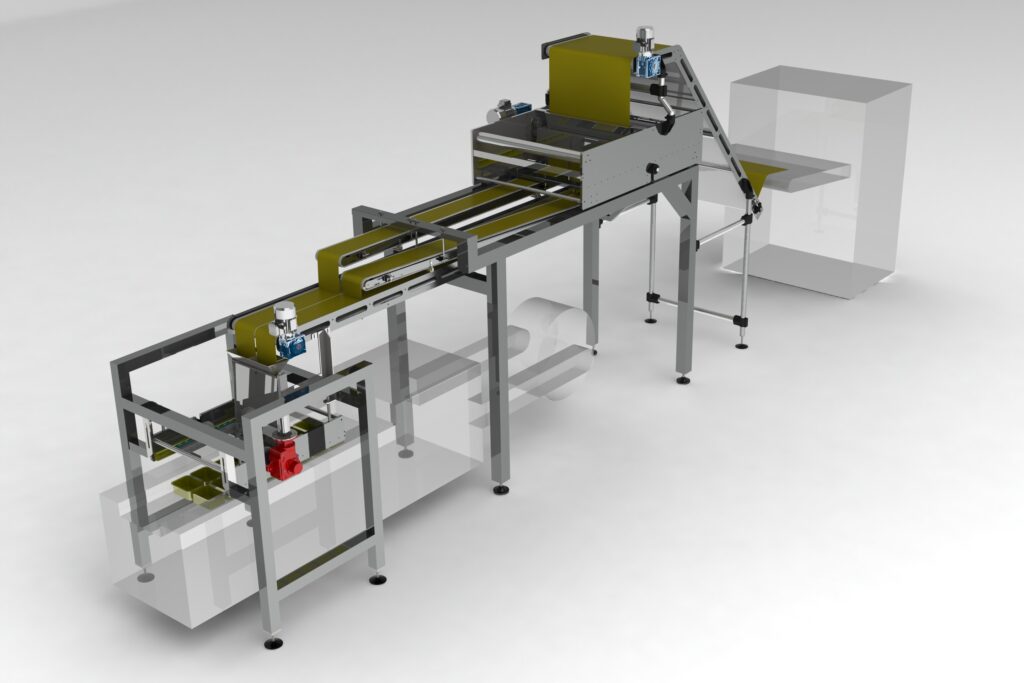

Let's now explore the core of dry pasta production:

Fresh pasta plants are ideal for producing pasta that is sold fresh and has a shorter shelf life compared to dry pasta. After extrusion or lamination and cutting, the pasta is immediately packaged and refrigerated. This type of pasta can be filled, such as ravioli, or unfilled, such as tagliatelle, catering to a variety of tastes and preferences. Let's move on to a detailed description of the fresh pasta production process.

Types of Fresh Pasta

Fresh pasta can vary widely, including filled varieties like tortellini and ravioli, as well as simple types like linguine and tagliolini. The freshness of the pasta provides a unique flavor and texture that many people prefer over dry pasta.

The gnocchi plants specialize in the production of these delicious potato and flour-based pasta dumplings. These facilities include machinery for dough preparation, shaping, and packaging, ensuring efficient and high-quality production. The production process begins with:

Pre-cooked pasta plants are designed to reduce preparation times in the kitchen. These plants produce partially cooked pasta through a process that includes partial cooking, rapid cooling, and packaging. This type of pasta is often used in ready meals, ensuring convenience without compromising on taste.

The production process is as follows:

The plants specialize in the production of pasta sheets. These facilities laminate the dough into thin sheets and cut them into desired sizes. Often, they also include pre-cooking of the sheets before packaging. In addition to lasagna, these plants can produce other types of laminated pasta, thus meeting diverse market needs. The production process includes the following stages:

Innovation and Technology

Technology in pasta production plants is constantly evolving. Innovations in machinery and production processes enable the production of high-quality products more efficiently. These advanced solutions not only meet the growing demand but also maintain high standards of quality and safety.

Compliance with Food Safety Standards

Pasta production plants must adhere to strict food safety standards, including hygiene regulations, quality controls, and product traceability. Ensuring food safety is essential to protect consumers and maintain trust in the products.

FAQ