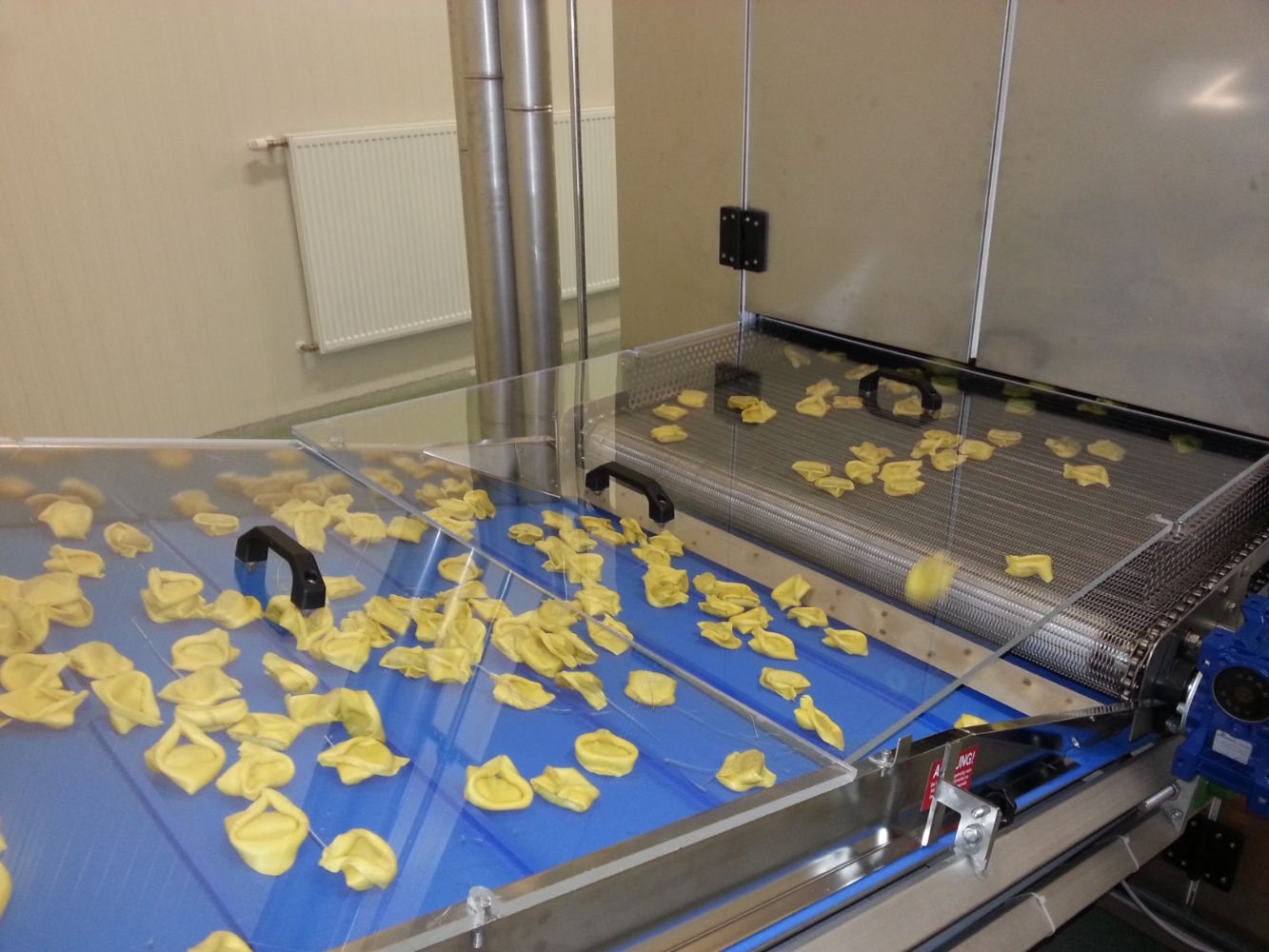

Pasta conveyor belts are systems designed to optimize the thermal treatment of pasta. Thanks to their adaptability, they can meet different production requirements.

For fresh or pre-cooked pasta, for example, they are used in pasteurisation processes, where high temperatures and steam jets eliminate bacteria and ensure the food safety of the product.

During the production of dry pasta, on the other hand, they are mainly used in the drying process, a crucial step in the long-term shelf life of the product. Furthermore, conveyor belts can also be included in the deep-freezing or cooling of pasta processing.

Conveyor belts used in pasta production must meet specific requirements to ensure efficiency, safety and durability.

Here are some of their main characteristics.

In order to increase the efficiency of the production line, it is also possible to adjust the belt speed and add accumulation systems that allow continuous production.

Developed both as spiral systems and as a linear tunnels, Sarp conveyor belts can respond to specific production requirements, ensuring flexibility and adaptability. They can be integrated into new or existing production lines.

After an initial assessment and a careful analysis of the characteristics and requirements of the products, we custom design the conveyor belt keeping in mind the specific needs of the production flow.

All types of pasta, including fresh, dry, filled, pre-cooked, gnocchi, etc. This also includes all ready-made meals packaged in trays.

Yes, each plant is customizable to align with the unique needs of the customer.

Building a plant usually takes 4 to 6 months, influenced by the customization and scale of the project.

There isn’t a minimum order; each system is customized to suit the production needs of the customer.

We serve markets internationally, with a primary focus on Northern and Southern Europe, the Americas, Russia, former CIS countries, and the Middle East.

Installing the plant can take from 15 days to a month and a half, depending on its complexity.

Our advantage is that we customize every project, unlike selling predefined models.